2026 Top Terry Towel Weaving Machine Innovations and Trends?

The terry towel weaving machine industry is undergoing significant innovation as we approach 2026. Recent reports indicate that advancements in automation and energy efficiency are shaping production processes. According to a study by Global Textile Machinery, the demand for high-performance terry towel weaving machines is projected to grow by 15% annually through 2026.

Industry expert Dr. Emma Thompson states, “The integration of IoT technology in terry towel weaving machines is revolutionizing quality control.” This statement underscores the shift toward smarter machinery, which allows for real-time monitoring and improved product quality. Such innovations present both opportunities and new challenges for manufacturers navigating the evolving landscape.

However, as companies adapt to these trends, there remains a need for reflection. The initial investment in advanced terry towel weaving machines can be substantial. Some firms struggle to balance innovation with cost-effectiveness. It is clear that while the future holds promise, the journey to modernization requires careful consideration and strategic planning.

Overview of Terry Towel Weaving Machines: Current State and Importance

Terry towel weaving machines are crucial in textile manufacturing. They create plush and absorbent towels that are essential for everyday use. The current state of these machines showcases significant advancements in technology. They optimize efficiency and quality, meeting the rising demand for luxurious textiles.

However, there are challenges. Some manufacturers struggle with outdated machinery, leading to production delays. The integration of innovative features can be costly. Manufacturers must weigh the benefits of newer technologies against financial constraints. Also, maintaining a balance between speed and quality is essential.

Sustainability is another area of concern. The industry is under pressure to minimize waste. Many weaving machines still consume excessive resources. This raises questions about long-term viability. As the market evolves, the importance of efficient and eco-friendly solutions becomes paramount.

2026 Innovations in Terry Towel Weaving Machines

This chart illustrates the adoption rates of various innovations in Terry Towel weaving machines anticipated for 2026. Automation is leading the way, with a significant 75% adoption rate, indicating a strong trend towards increasing efficiency in production. Other features, such as eco-friendly materials and smart technology, also show promising adoption rates, reflecting the industry's shift towards sustainability and advanced technology integration.

Key Innovations in Terry Towel Weaving Technology for 2026

The terry towel industry is undergoing significant transformations in 2026. With the demand for sustainable products rising, innovations are crucial. New weaving techniques focus on reducing material waste. Reports indicate that more than 30% of traditional weavings result in textile waste. This issue drives the industry to adopt more eco-friendly practices.

Automated weaving machines are gaining traction. These machines enhance precision and speed, allowing for greater output. An estimated 20% increase in efficiency has been reported with the latest models. However, challenges remain. The initial costs can be prohibitive for smaller manufacturers. A careful balance is needed between investment and return.

Digital integration is also a key trend. Smart machines can monitor production in real-time. This technology can lead to near-zero downtime. Recent studies show that companies using this tech see maintenance costs drop by 15%. Yet, reliance on technology may also introduce new vulnerabilities. Manufacturers must remain vigilant in cybersecurity and ensure the long-term viability of these innovations.

Sustainable Practices in Terry Towel Manufacturing and Weaving Processes

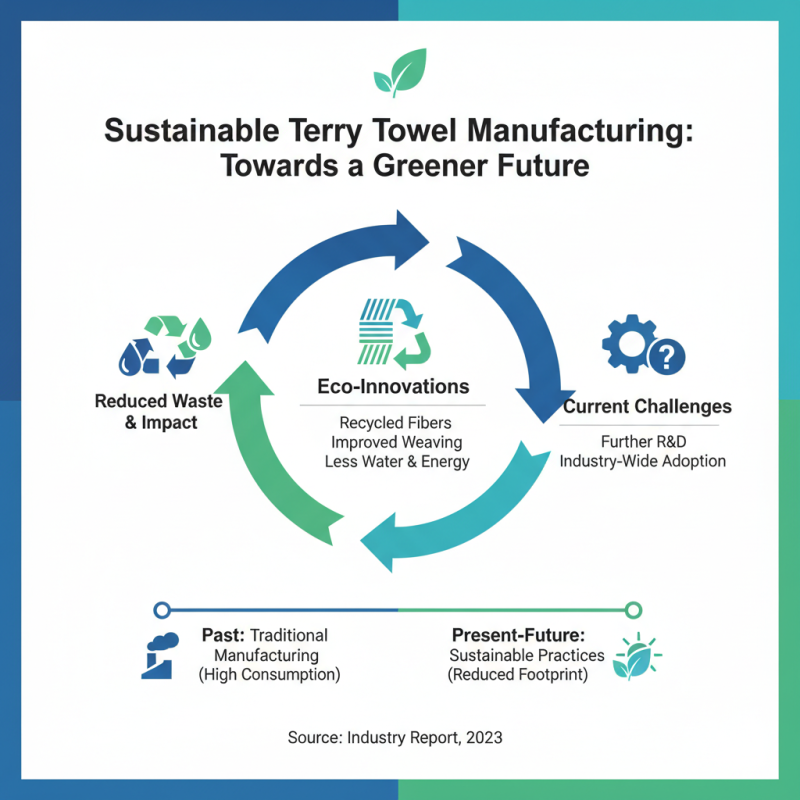

In recent years, sustainable practices have gained significant traction in the terry towel manufacturing sector. Weaving processes are evolving to reduce waste and environmental impact. For instance, using recycled fibers is becoming more common. These innovations help in cutting down water and energy consumption during production. The manufacturing process is not perfect; there are still hurdles to overcome.

Some facilities struggle with implementing eco-friendly methods fully. Not all manufacturers have access to sustainable materials. This inconsistency can lead to challenges in meeting sustainability goals. Yet, there is a push for better practices. Partnership with local suppliers can improve material sourcing while supporting the community.

Investments in technology are crucial. Advanced weaving machines increasingly integrate energy-efficient features. These machines can minimize fabric waste significantly. However, adapting to new technology may require significant time and resources. Businesses must reflect on their practices and look for ways to improve sustainably. The shift towards eco-consciousness is a journey with both successes and setbacks.

Emerging Trends in Automation and Smart Technology in Weaving Machines

The weaving industry is witnessing a significant shift toward automation and smart technology. According to recent industry data, the adoption rate of automated weaving machines has increased by nearly 40% in the past three years. This trend is a response to the growing demand for efficiency and precision in fabric production.

Smart technology integration is key. Many manufacturers are now using IoT devices to monitor machine performance in real time. These devices provide valuable insights, allowing for better maintenance and reduced downtime. A report indicates that industries leveraging smart technology can achieve up to 20% cost savings annually. However, challenges remain.

Not all weaving facilities are equipped with the infrastructure needed for these innovations. Some companies struggle to train their workforce on new technologies. This gap can hinder progress. Moreover, the initial investment in smart technology can be substantial. Industry experts note that without careful planning, companies might face financial setbacks before reaping the benefits. Addressing these issues is crucial for the widespread adoption of high-tech weaving solutions.

Impact of Consumer Demands on Terry Towel Weaving Machine Designs

As consumer demands shift towards sustainability and customization, the terry towel industry faces new challenges. Recent market research indicates that eco-friendly materials have become a priority for over 70% of consumers. This trend pushes manufacturers to innovate their weaving machines. The goal is to produce towels that are not only soft and absorbent but also environmentally responsible.

The impact of these consumer preferences is significant. Weaving machines are now designed for versatility. They can handle different fiber types, including organic cotton and bamboo. According to industry reports, around 65% of manufacturers are investing in technology that allows for easy adjustments. This flexibility caters to the growing demand for personalized products and limited editions.

However, not all companies are able to keep up. Some traditional manufacturers still rely on outdated machinery. This can lead to inefficiencies and higher waste. As market expectations continue to evolve, the pressure mounts. The challenge remains to blend innovative designs with consumer desires while maintaining quality and production efficiency. The future of terry towel weaving machines hinges on realizing these consumer-driven innovations.

2026 Top Terry Towel Weaving Machine Innovations and Trends

| Innovation | Description | Impact on Design | Consumer Demand Influence |

|---|---|---|---|

| Eco-Friendly Materials | Using recycled fibers and sustainable materials to reduce environmental impact. | Designs that prioritize sustainability with minimalistic aesthetics. | Growing consumer awareness about environmental issues leads to demand for eco-friendly textiles. |

| Smart Weaving Technology | Integration of IoT and AI for real-time monitoring and quality control. | Machines feature automated adjustments for enhanced production efficiency. | Consumers demand higher quality and consistency, driving tech advancement. |

| Customized Patterns | Machines capable of creating unique patterns and designs on demand. | Flexible looms that cater to individual preferences and market trends. | Increased consumer desire for personalized home textiles encourages diverse offerings. |

| Energy Efficiency | Machines designed to minimize energy consumption during production. | Innovative designs that maximize output while reducing power usage. | Rising energy costs and consumer preference for energy-efficient products prompt design changes. |

| Advanced Fiber Technology | Utilization of advanced fibers that provide superior softness and durability. | Modern designs that focus on enhancing tactile experience and longevity. | Consumers increasingly value product quality, impacting material choices. |

Related Posts

-

Why Understanding Fabric World is Essential for Fashion and Design Trends

-

Top 10 Smit Weaving Machine Features You Need to Know

-

10 Essential Tips for Using a Carbon Weaving Machine in 2026

-

Why Terry Towels Are Essential for Your Home and How to Choose the Best Ones

-

How to Effectively Use Textile Treatment for Enhanced Fabric Durability

-

How to Choose the Best Carbon Fiber Weaving Machine for Your Needs