How to Effectively Use Textile Treatment for Enhanced Fabric Durability

In today's competitive textile industry, achieving enhanced fabric durability has become essential for manufacturers and consumers alike. One of the most effective strategies employed in this endeavor is the use of textile treatment. Renowned textile expert Dr. Emily Henderson emphasizes the significance of this process, stating, "The right textile treatment can transform a basic fabric into a resilient material that withstands the test of time and usage." This underscores the fact that innovative treatments not only improve the performance of textiles, but also extend their lifespan, offering both economic and environmental benefits.

Textile treatment encompasses a variety of techniques designed to enhance the durability of fabrics, from water repellency to anti-wrinkle properties. As the demand for high-performance textiles grows, it is crucial for manufacturers to understand the different types of treatments available and their applications. Properly implemented treatments not only protect fabrics from wear and tear but also enhance their overall aesthetic appeal, making them more attractive to consumers. By focusing on effective textile treatment strategies, the industry can continue to evolve, providing superior products that meet the modern consumer's needs and expectations.

Understanding the Importance of Fabric Durability in Textile Treatment

Understanding the importance of fabric durability in textile treatment is crucial for both manufacturers and consumers. Fabric durability is defined by a material's ability to withstand wear, pressure, or damage, effectively extending the lifecycle of textiles. According to a report by the American Association of Textile Chemists and Colorists (AATCC), fabrics treated for durability can last up to 50% longer than untreated counterparts. This is particularly relevant in industries such as automotive and outdoor gear, where wear and tear can significantly affect performance and safety.

Incorporating proper textile treatments not only enhances durability but also improves the overall quality of the fabric. Techniques such as DWR (Durable Water Repellent) and antimicrobial treatments can protect against moisture and microbial growth, respectively. These treatments are essential in ensuring fabrics maintain their integrity even in challenging environments. Furthermore, the textile industry reports that consumer demand for long-lasting materials is increasing, with 65% of shoppers willing to pay more for durable products. This highlights the necessity for manufacturers to invest in effective textile treatments that align with consumer expectations.

Tips for enhancing fabric durability:

1. Choose the right treatment: Select treatments that cater specifically to the end-use of the fabric; for instance, moisture-wicking high-performance treatments for athletic wear.

2. Regular maintenance: Encourage consumers to follow proper care instructions to prolong the life of treated fabrics, as cleaning methods can significantly impact durability.

3. Test before full-scale application: Conduct lab tests on fabric samples to gauge the effectiveness of chosen treatments, ensuring they meet durability standards before mass production.

Common Textile Treatments for Enhancing Fabric Durability

When it comes to enhancing fabric durability, various textile treatments can significantly increase resilience and longevity. One popular method is water resistance treatment, which involves applying a breathable membrane or a durable water repellent (DWR) finish. This treatment helps fabrics repel water, reducing the chances of stains and damage from moisture. This is particularly beneficial for outdoor gear, where exposure to the elements is frequent and inevitable.

Another effective treatment is anti-microbial finishing, which inhibits the growth of bacteria and fungi on fabrics. This is crucial for items that come into regular contact with the skin, such as athletic wear and undergarments. By reducing odor and ensuring hygiene, anti-microbial treatments enhance overall fabric performance and user comfort. Additionally, applying UV protection treatments can shield fabrics from the harmful effects of sunlight, ultimately prolonging the color and integrity of outdoor textiles. Through these various textile treatments, users can achieve fabrics that not only withstand daily wear and tear but also maintain their aesthetic appeal over time.

Step-by-Step Guide to Applying Textile Treatments Correctly

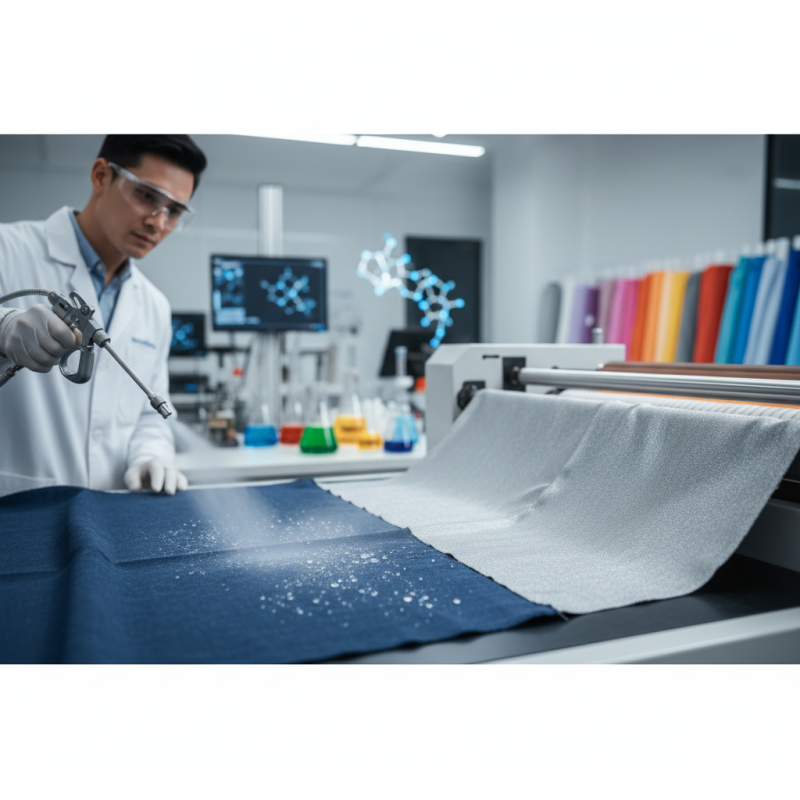

Textile treatments are essential for enhancing the durability of fabrics, allowing them to withstand wear and tear while maintaining their appearance. To apply textile treatments effectively, it is crucial to follow a step-by-step approach. Start by cleaning the fabric thoroughly to remove any dirt or oils that may hinder the treatment's effectiveness. Use a gentle detergent and ensure that the fabric is completely dry before proceeding to the next step.

Once the fabric is clean and dry, select the appropriate textile treatment based on the desired outcome, whether it’s water resistance, stain protection, or UV resistance. Apply the treatment evenly using a spray bottle, sponge, or brush, paying special attention to seams and high-wear areas. Allow the fabric to absorb the treatment for the recommended time before rinsing or heat-setting, as specified in the product instructions.

**Tips**: Always test the treatment on a small, inconspicuous area of the fabric before full application to ensure compatibility and prevent any adverse reactions. Additionally, consider the environmental impact of the treatments you choose, opting for eco-friendly options when available to protect both the fabric and the planet. Regular maintenance, such as reapplying treatments as needed, will also help prolong the life of your textiles.

Evaluating the Effectiveness of Textile Treatments on Fabric Longevity

Evaluating the effectiveness of textile treatments on fabric longevity involves a thorough examination of various methods designed to enhance durability. Different treatment techniques, such as chemical finishes, coatings, and mechanical processes, can significantly impact how fabrics withstand wear and tear over time. For instance, applying water repellents or abrasion-resistant finishes can extend the life of textiles by reducing the effects of moisture and friction, which are common causes of fabric deterioration.

Additionally, laboratory tests and wear trials are critical for assessing the long-term performance of treated fabrics. Factors such as colorfastness, resistance to environmental conditions, and the fabric's overall structural integrity are measured to provide a clear picture of durability. Understanding how different treatments interact with specific fabric types not only informs manufacturers about effective applications but also assists consumers in making informed choices about their textile purchases. Ultimately, a comprehensive evaluation of textile treatments supports the advancement of industry standards for fabric longevity and sustainable practices in textile production.

How to Effectively Use Textile Treatment for Enhanced Fabric Durability

| Textile Treatment Method | Average Longevity Increase (%) | Benefits | Cost Efficiency Rating (1-5) |

|---|---|---|---|

| Water Repellent Treatment | 30% | Prevents moisture damage | 4 |

| UV Protective Coating | 25% | Blocks harmful UV rays | 3 |

| Anti-Microbial Treatment | 20% | Reduces odors and bacteria | 4 |

| Stain Resistant Finishes | 15% | Easier to clean and maintain | 5 |

| Flame Retardant Treatment | 40% | Increases safety in use | 3 |

Maintenance Tips for Fabrics with Enhanced Durability Treatments

When it comes to maintaining fabrics that have undergone enhanced durability treatments, it is crucial to adopt specific care methods that preserve their quality and extend their lifespan. First and foremost, it is important to follow the manufacturer's care instructions. Washing these fabrics with mild detergents and on gentler cycles minimizes wear and tear. Additionally, opting for air drying instead of machine drying can help maintain the fabric's integrity, as excessive heat may degrade the treatment over time.

Regular inspections and spot cleaning are also vital for maintaining treated fabrics. Check for stains or signs of wear promptly, and tackle any spills using a soft cloth and mild soap. Avoid abrasive cleaning materials, as they can damage the fabric’s surface and the protective treatments applied to it. Furthermore, storing these fabrics in a cool, dry place, away from direct sunlight, helps prevent fading and degradation of the enhanced treatments, ensuring that your textiles remain durable and vibrant for years to come.