What is a textile weaving machine and how does it work?

A textile weaving machine is an essential tool in the fabric production industry. It transforms yarn into cloth through a complex process. The machine interlaces threads with precision, creating various patterns and textures.

Understanding how a textile weaving machine operates helps appreciate its role in making garments. It consists of several parts, including warp beams and shuttle boxes. Each component plays a vital role in the weaving process. However, mastering this machinery requires skill and experience. Many beginners struggle to operate it effectively.

Despite its importance, the textile weaving machine faces challenges today. Changing fashion trends and sustainability concerns impact production. Seeking innovation can be both exciting and daunting. The balance between traditional techniques and modern advancements needs reflection.

What is a Textile Weaving Machine?

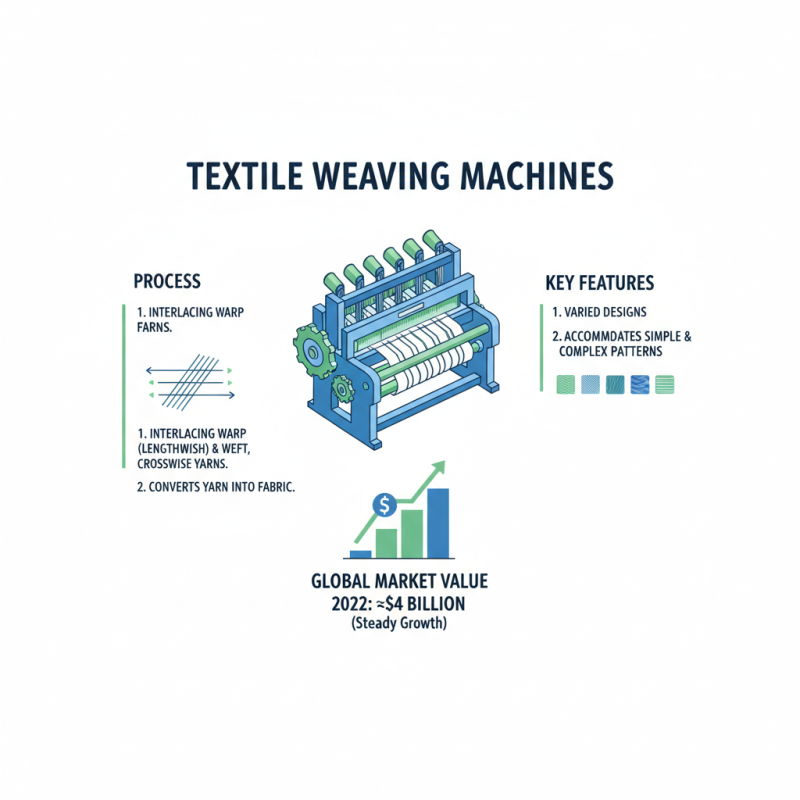

A textile weaving machine is a crucial component of the textile industry. It converts yarns into fabric through various weaving techniques. These machines operate by interlacing two sets of threads: the warp (lengthwise) and the weft (crosswise). The loom's design varies, accommodating different types of fabrics, from simple to complex patterns. According to industry reports, the global weaving machinery market was valued at approximately $4 billion in 2022, showing steady growth.

Understanding how these machines work is essential. They employ mechanisms like the shuttle or rapier to insert the weft thread. These techniques influence the fabric's texture and strength. Insights from a recent study highlight that efficient weaving machines can increase production speed by up to 30%. However, many manufacturers face challenges. Some machines may have limitations in fabric variety or efficiency. Reflection on these factors can lead to better investment decisions.

**Tips:** Ensure regular maintenance of your weaving machine. Keeping it in optimal condition prolongs its lifespan. Consider investing in training for operators. Knowledgeable staff can enhance productivity significantly. Continuous assessments of weaving techniques can also lead to improvements in quality.

History and Evolution of Weaving Machines

The origins of weaving machines date back to ancient civilizations. The earliest devices relied on manual labor and simple mechanisms. As societies advanced, so did the technology behind these machines. For instance, the loom made its debut over 5,000 years ago. It was a significant step forward in textile production.

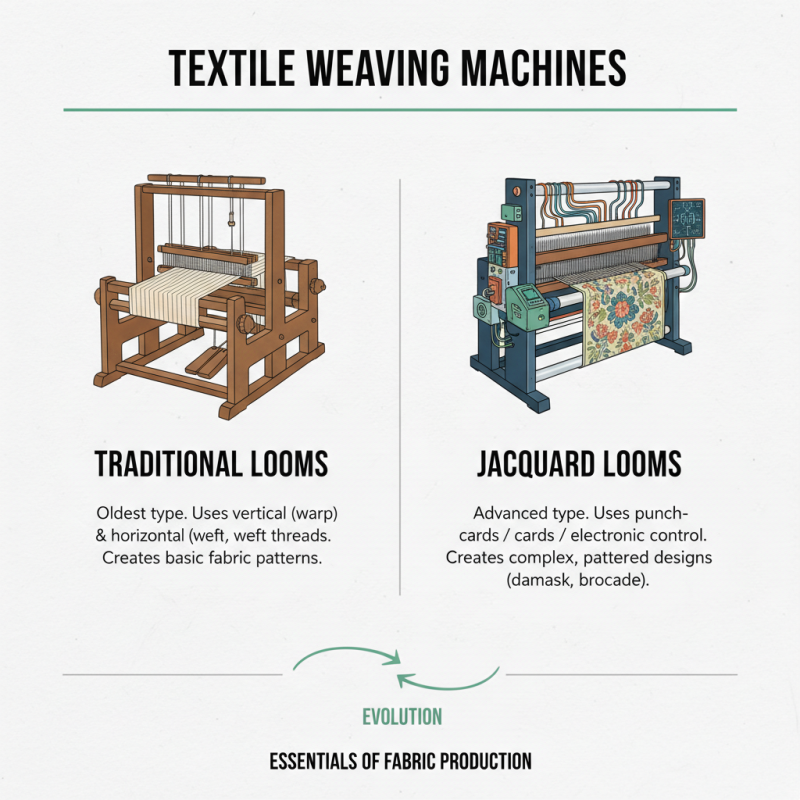

In the 18th century, the Industrial Revolution brought profound changes. The invention of the Jacquard loom revolutionized weaving by allowing automated patterns. Reports indicate that this increased production efficiency by up to 50%. Moreover, these innovations set the stage for more complex weaving machines. By the 19th century, power looms began to dominate. They could produce textiles at an unprecedented scale, yet they also prompted debates about labor practices. Workers faced harsh conditions as machines replaced manual skills.

Today, weaving machines incorporate advanced technologies like computer-assisted design. These machines can produce intricate designs with minimal human intervention. According to industry reports, the global textile machine market is projected to reach $20 billion by 2025. However, reliance on automation raises questions. Will the craft of traditional weaving survive amidst growing dependence on technology?

Types of Weaving Machines and Their Functions

Textile weaving machines are essential in the fabric industry. Various types of machines cater to different weaving techniques. Looms are one of the oldest types of weaving machines. They use vertical and horizontal threads to create fabric patterns. Jacquard looms, on the other hand, allow for intricate designs. They use a series of punched cards or electronic controls for complex patterns.

Rapier looms are known for their speed and versatility. This type handles both light and heavy fabrics. They use a rapier to carry the weft thread across. A few other types include air-jet and water-jet looms. These machines employ air or water jets to insert weft yarn efficiently. Each type has its unique advantages and limitations.

Often, the selection of a weaving machine depends on production needs. Speed is essential, but so is the quality of the fabric. Sometimes, balancing speed and quality can be challenging. Operators must understand the machine functions well. Failing to do so could lead to defects in the fabric. It’s crucial to keep refining techniques and adapting to new technologies.

How a Textile Weaving Machine Operates

A textile weaving machine plays a crucial role in the fabric manufacturing process. These machines interlace threads to produce textiles of varying patterns and densities. By 2021, the global textile machinery market was valued at approximately $25 billion, showcasing its importance. The operation begins with loading the warp threads onto a beam. These threads are then pulled tight across the loom.

As the loom operates, the weft thread is fed through by a shuttle or a jet of air. This interlacing creates fabric. Different types of weaving techniques, such as plain weave or satin weave, yield diverse textures and qualities. It's fascinating that these machines can run at speeds of up to 1,000 picks per minute, depending on the fabric type. Yet, the precision of the weave often relies heavily on the machine’s calibration. Errors in tension or alignment can lead to defects.

Despite advancements, textile weaving machines still face challenges. The energy consumption of these devices is significant, representing a concern for manufacturers. Reports indicate that nearly 30% of energy used in textile production can be linked to machinery. Reflecting on this aspect, there is a growing need for innovation to enhance efficiency. Balancing performance with sustainability remains a critical issue in the industry.

Textile Weaving Machine Production Overview

Key Components of a Weaving Machine and Their Roles

A textile weaving machine is a complex setup designed to interlace threads. Understanding its key components helps us appreciate its functionality. The primary parts include the warp beam, shuttle, and reed.

The warp beam holds the vertical threads, also known as the warp. These threads are essential for creating the fabric's structure. The shuttle, on the other hand, carries the horizontal threads, known as the weft. This back-and-forth motion creates the weave. The reed pushes the weft into place, ensuring tightness and uniformity in the fabric.

Each component plays a vital role in the weaving process. However, the machine's efficiency can sometimes falter. Thread breakage or misalignment can cause delays. Operators need to regularly check each part to prevent errors. Even seasoned users may overlook minor issues. Addressing these complexities requires patience and attention to detail.

What is a textile weaving machine and how does it work? - Key Components of a Weaving Machine and Their Roles

| Component | Description | Role |

|---|---|---|

| Warp Beam | Holds the warp threads that run lengthwise in the fabric. | Provides the foundation for weaving by supplying the vertical threads. |

| Heddles | Threaded through the warp threads to control their movement. | Helps create the shed by lifting specific warp threads for the weft insertion. |

| Reed | A comb-like device that separates the warp threads and pushes the weft into place. | Ensures even spacing of the threads and helps pack the weft threads into the fabric. |

| Shuttle | Carries the weft thread back and forth through the shed. | Facilitates the weaving process by inserting the weft thread into the warp threads. |

| Take-up Roll | Rolls up the finished fabric as it's woven. | Collects the fabric produced during the weaving process. |

Related Posts

-

How to Choose the Best Carbon Fiber Products for Your Needs?

-

2026 Best Fabric Weaving Techniques and Innovations for Textile Industry?

-

10 Essential Tips for Using a Carbon Weaving Machine in 2026

-

Why Terry Towels Are Essential for Your Home and How to Choose the Best Ones

-

How to Choose the Right Home Textile for Every Room in Your House

-

Why Understanding Fabric World is Essential for Fashion and Design Trends